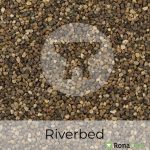

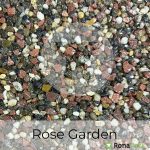

RonaDeck Resin Bound Surfacing is a resin bound aggregate surface for pedestrian and light vehicular traffic. RonaDeck Resin Bound surfaces are decorative and functional, seamless and slightly flexible. Furthermore, the open matrix allows water to drain through to the base. As a result water ponding is eliminated, allowing water to drain to natural water courses, land drains or planted areas. The surfacing may be applied to SuDS compliant bases and sub-bases, reducing the impact of new development on flood risk, or to impermeable bases laid to adequate falls. Edgings created from brick, stone, timber or steel should be installed to retain and protect the resin bound surfacing.